19. Mechanical check-list for new fan start-up

In a previous article, we wrote about the Aeraulic precautions and controls to execute a new fan start-up.

Concerning the rotating machines, we have also to ensure a right mechanical Start-up in order to keep safe the persons, as well as for the life-time machine components, whatever its size or motorization. Especially in case of process machines with an important peripheral velocity, or when dedicated to work in severe operating conditions (Hot/wet dusty gas, high ambient temperature…)

Any good mechanical engineer able to maintain rotating machines is able to carry out these checks, but often, when the installation was carried out by a third party company, or in order to keep running the warranty, we are offering our services a short time before commissioning. In this case, our specialist will come on site, once the machine is installed, and will perform the following operations:

- Check sub-units mounting (according drawings supplied by us)

- Check anchoring seal and fan’s leveling

- Check bolts tightening of fan’s various flanges (by sampling)

- Check bolts tightening of bearing and anchoring seal

- Check bearings (general state and clearance tip) and bearing housing (lubrication)

- Check clearance housing

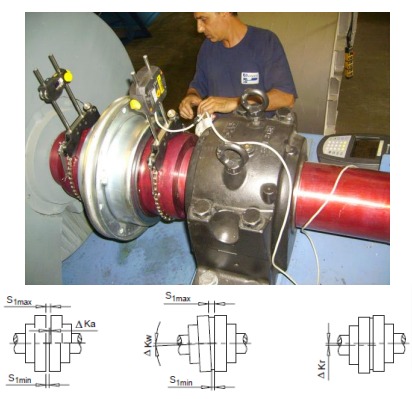

- Check V-belts alignment or fan/motor shaft

- Check flexible connection mounting

- Check damper and/or inlet vane control: opening direction, MAX/MIN range opening, operation with actuator

- Rotation tests: 2 hours minimum operation with:

- Vibration measurements on the motor-fan unit

- o Temperature measurements on each bearing

- o Balancing adjustment if necessary

Often the fans are delivered a long time before commissioning, in order to realize a sea transport or to fit to new plant mounting planning.

In case of long-term storage before first commissioning or long-term production interruption, it is very important to ensure sheltered, tempered and vibration-free storage conditions.

The new fan user will care about filling the bearings with appropriate grease, which will be renew again before commissioning with correct quantity recommended in our instruction notice. This step will protect the bearings for 6 months. If storage term is up to 6 months, then the bearings should be

cleaned and refilled with new grease.

Despite this safety measure, our specialist will proceed a minutely detailed checking of bearings state before commissioning.

During long-term storage, the impeller weight may damage the bearing raceways by a mark. Therefore it is essential to rotate the impeller once a week during all the storage period.

In case of belt driven arrangement, it is necessary to loosen the belts or better, to store it in dry and tempered place. Just before commissioning, the belts will be tensioned again with a check of motor and fan shaft alignment.