24. Noise, it is the empty barrels that are the noisiest

The noise of the fansjhgjhg (magnificent sound boxes) is due to several causes. Aeraulic reasons are often more impacting than mechanical ones.

Aeraulic noise origin.

Noise is due to the movement of the impeller. The impeller is equipped with blades producing rotating wakes at the impeller speed (N tours/s). Those wakes are generating a sound increasing when they are facing fix obstacles as for example the casing fan. If the impeller is equipped with b blades, the noise generated will have as main frequency bN Hz. This noise is similar to a warning horn possessing a spectral line.

Noise is due to turbulences. The pressure fluctuations generated by the turbulence inside the fan cause noise with a continuous spectrum of frequencies. However, turbulences can excite resonances which reinforce certain frequencies of the spectrum.

We also distinguish the noise due to gyration (rotating separation similar to wakes hitting fixed obstacles) less impacting than the previous ones, as well as noise related to the instability of the flow, also less impacting, except when the resonances are due to the pumping of the fan. The sounds emission is similar to certain music wind instruments (flute).

Mechanic noise origin.

Noises of mechanical origin are often negligible regarding airflow noise, except in certain circumstances.

They are due to:

- the drive motor, and in particular if it is controlled via a frequency converter,

- the bearings (shocks due to the defects of the bearing elements on their cage)

- the transmission

- the vibrations in case of balancing problems.

Efficiency and fan noise

The noise origins described above shows that the noise corresponds to a loss of energy. It is therefore not false to think that the maximum efficiency point of the fan will fit to the lowest noise point, among all the possible operating points along the flow / pressure curve.

Indeed, experience shows it and it is quite simple to explain why: there is always a point for which the speed triangle at the impeller inlet is the most suitable to the input geometry of the impeller. This point is called “fan adaptation point”, and is the point where the flow enters the channel between the blades with the minimum of separation, with consequently the lowest shock losses. It is this point which corresponds to the best efficiency of the fan.

Therefore, as much as we move far away from the point of maximum efficiency, the noise increases, and

especially at the left of the curve coming close to the instability and pumping zone of the fan.

Fighting the noise

The noise control of the fans will therefore be carried out according to 2 ways:

1. Use of high efficiency and mechanically robust fans to eliminate possible sources of vibration.

2. Acoustic barrier with respect to the environment:

- Insulation of the volute using Rockwool maintained by a galvanized sheet or aluminum plates,

sometimes reinforced by the bonding of a heavy absorbent material on the inner side of this sheet. - Complete cowling of the fan and motor taking into account that is ventilated by fresh air via a

soundproofed opening to the outside, but also by ensuring, through adequate ventilation, that the

ambient temperature inside the cowling is compatible with bearings (in the case of hightemperature fans dissipating a calorific energy). - Insertion of silencers in the pipes before or/and after the fan in order to avoid the noise propagation.

Influence of the speed and the size of the fan at constant Flow/pressure

Please note that in order to carry out the same flow / pressure program, the use of a larger fan with lower speed does not significantly modify the radiated noise, as it is a function of the loss of energy, itself proportional to the flow / pressure program which remains constant. The few decibels gained by the selection of a fan at lower speed, are obtained by a reduction of mechanical noise origin and by the fact that the main frequency of the fan moves towards low frequencies for which the ear is less sensitive.

Influence of the speed and size of homothetic fans, at their maximum point of return.

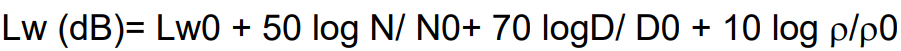

The simplified formula below is interesting to get an idea of the influence of the working conditions (we do not take into account the possible variation of sound velocity in the gas as well as the Mach Number).

If we set Lw0 as the acoustic power of a given fan of diameter D0, rotating at N0 RPM and conveying a gas of density r0, another fan of the same family (ie homothetic) will develop an acoustic power equal to:

As long as the 2 fans work at their maximum efficiency level.