27. Working point regulation by inlet vane control.

Inlet Vane Control description

The Inlet Vane Control is a regulation device to set up a desired working point of the fan. It is installed straight ahead on the suction flange.

The device is equipped by blades with sector shapes, fixed on radial axis. Rotating around this axis thanks to the linkage drive, the blades will create for the gas a variable cross surface.

The pre-rotating movement (in the fan’s rotating direction) implemented to the gas affects the speed triangle at the impeller entry. Therefore the energy imparted to the fluid is modified. The curve flow pressure can be modulated at your wish with an alteration of the efficiency much more weak than a common damper at any point of the system.

The advantage of the inlet vane control comparing a common damper is that the damper creates a new pressure drop without decreasing the effective impeller work. With an inlet vane control we spare the impeller to produce any undesirable pressure.

Functional principle

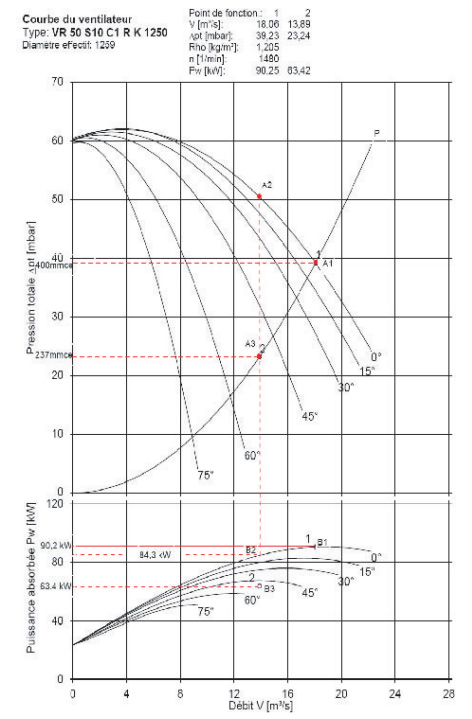

The graph below shows this advantage on a constant resistive circuit.

When we wish to decrease the flow for a fan operating on the circuit represented by the parabola P, if we close a damper, then the operating point of the fan moves from A1 to A2.

Comparing the pressure drop necessary that we can read on A3 on the Functional principle parabola, we use in total loss the pressure A2A3 through the damper. A

significant proportion of the power read on B2 is transformed into heat

while crossing the damper. On the other hand, if we use an inlet vane control, we will close it with an angle of 50°. The curve of the fan is deteriorated in order to assure the pressure A3 needed but with an absorbed power read on B3. The

difference between B2 and B3 is the “saved power” thanks to inlet vane control.

The same exercise could be done when we wish to modify the flow with constant pressure (the working point moves horizontally regarding A1) or if we wish a constant flow with variable pressure (the working point moves vertically regarding A1).

Properties

- The inlet vane control is a devices with simple construction and very robust.

- They allow an easy adaptation regarding the system variations because the fan’s curve is replaced by a network of curves.

- The blades can swing quickly while following precisely the operating situation of the system. This

is a significant advantage regarding regulation with variable speed drive which is weakened by the

impeller inertia. For example, during the quenching of the glass which consist in a brutal cooling of the glass after heating step, it is really important to be equipped with a fast regulation device in order to “seize” the glass by a cold blow air. Between to units of glass to be quench, the inlet vane control is closing quickly decreasing by the way the absorbed power. - The inlet vane control blades are rarely subject to wear and to clogging, because they are stationary, and the air speed at the inlet vane control is quite weak.

- The curve of the fan corresponding to a partial closing of the inlet vane control is strongly falling, with the consequence that at low flow operations the upward curve is deleted. This upward curve is an instable zone in which the fan may work with a “pumping” effect. The inlet vane control allow

to remove that risk and also to make easy the fans parallel arrangement. - To close an inlet vane control during the fan starting allows to reduce the absorbed power because of a low flow.

- It is important to note that a closed inlet vane control is not a perfect sealed device taking into account its construction. It should not be used to operate a total closing of the system.

- It is hard to get fine adjustment of low flows, because starting from closed position, a small opening of the inlet vane control provoke a quick increase of the flow. In the other hand, at large flows, a large movement of the inlet vane control is needed to obtain a flow variation. This gives a large scale in order to operate fine adjustments.

- The inlet vane control might be handled manually, via an electrical actuator or a pneumatic actuator,

enslaved to a system of depression measurement, for example.