13. Critical speed of the shaft : essential setting in the fan design

Introduction

The mechanical design of a fan is surely depending on economic matters leading to steel and thickness choices, with a design including the less possible manufacturing hours, in order to get a competitive sale price.

However, the fan is a rotating machine, it is mandatory to calculate it rigorously, with sufficient safety factor, to ensure a safe operation as well for the operating staff but also for the surrounding equipment.

Considering the impeller mechanical strains calculation, the critical speed shaft is also an essential parameter of the fan sizing, giving the shaft diameter, the impeller weight, the sizing of the house bearing and the design of the frame able to support the entire fan for an optimal operation in acceptable vibratory conditions.

Let’s review the matter depending on the critical speed

Any object, deviated from its initial balanced position, swings around this position as soon as the action which deviated it is interrupted. This oscillation is a periodical movement which is a characteristic of the system. We call “natural frequency” the reverse system of this period.

All objects, including those called “rigid” are more or less flexible, and are subject to vibration at their natural frequency. The most common example is the “ruler”, firmly kept in one hand at the desk border; we apply then a force at the free side of the ruler. The natural frequency of this system is directly affected by the free side length of the ruler, in other words by the “rigidity” of the system. The frequency is low for a long free length, high if the free length is decreasing.

In free oscillation, it means subject to a single force, the object will retrieve its original balance state. However, if the exciting cause is by itself periodic, and operating at the same frequency that the system natural frequency, we observe that the vibrations ranges increases beyond limits, theoretically till the system breakage. The excitation frequency is then called “critical frequency”.

Ex.1. everybody does remember the child’s swing: imagine that at every return of the child sitting on it, the parent push lightly but with constant power, meaning at the equal frequency to the natural frequency of the “child -child’s swing” system, therefore, the movement range will increase becoming even dangerous for the child safety and with the necessity of stopping quickly the push on it.

Ex.2. we already watched this famous footage showing a bridge breakage due to the simple crossing of military troops walking at specific footstep with unhappily a frequency corresponding to the natural frequency of the bridge.

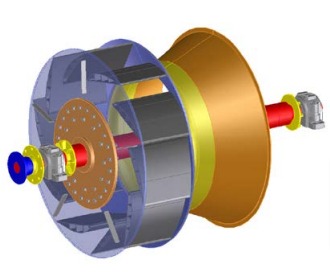

Application to the fan shaft

The shaft is flexible, taking into account a specific deflection under the action of the impeller weight. The impeller always has an

unbalance that gives rise to a centrifugal force at the rate of the shaft rotation.

So we have an excitation whose frequency is the rotational speed. If this rotational speed is equal to the shaft natural frequency, a resonance appears and the oscillations range of the shaft increases till the breakage.

It is necessary then, to size the shaft in order to get enough margin between the operational use condition and the critical speed, to avoid harmful vibrations as well for the fan and its direct surrounding.

The factors influencing the natural frequency are especially:

- The stiffness k : we saw above that the natural frequency increases with the stiffness.

- The mass m in movement: if we increase the mass hanged vertically at a spring, the movement goes slow,

therefore the frequency decreases.

The stiffness and the mass are reason for natural frequency variation in opposite direction and we got:

Fp=1/2π√k/m

We can also demonstrate that the stiffness k = P/f (P= weight / f= deflection).

Knowing that P=mg (mass x gravity acceleration), we got a new expression of the natural frequency:

Fp=1/2π√g/f

The critical speed Nc is equal to the natural frequency of the shaft Nc = 1/2π √k/m = 1/2π√g/f

A fan designed for 1500 RPM and with a deflection at the shaft of 0.35mm under the action of an impeller weight of 300 kg. This shaft gives a value of stiffness:

k= 300 x 9.81/0.00035= 8408571.

The critical speed will be Nc = 1/2π√8408571/300 =26.6 rd/s, or 1598 RPM.

Such a value is dangerous because too close to the nominal rotational speed (1500 RPM), in particular when the fan is operating with a variable speed drive allowing the increase of the speed for specific operational conditions. It is then mandatory to harden the shaft by increasing the diameter to decrease the deflection.

It is common to size a shaft in order to get a factor of 1.3 to 1.5 between the naturel frequency and the deisgn speed of the fan. 1.7 is also used in particular circumstances.