9. Torque stories

The variable speed drives are increasingly used for fan operations. The advantages of a VSD are:

- The cost price has considerably decreased this last 20 years and therefor quickly depreciated.

- They allow to start the fan without the Direct On Line current peaks ( 5 to 7 time the nominal current)

- They allow an important energy saving in regards to circuit strangulation by a damper or with an inlet vane control, while operating a lower speed.

- They allow a fan curve adjustment after any temporary or permanent change in the circuit.

- They allow reducing globally the noise of the machine when it is not needed to operate a full speed.

- They allow maintaining the length of life of the mechanical equipment (especially the bearings but also the impeller when operating with abrasive dust).

- In certain cases, they allow to avoid the use of belt transmission and therefor avoid the maintenance cost of the used belts.

The electrical motor sizing for a fan with variable speed is classical. However, it matters to remember some basic rules when we wish to run the fan at a higher speed level than nominal.

Reminder:

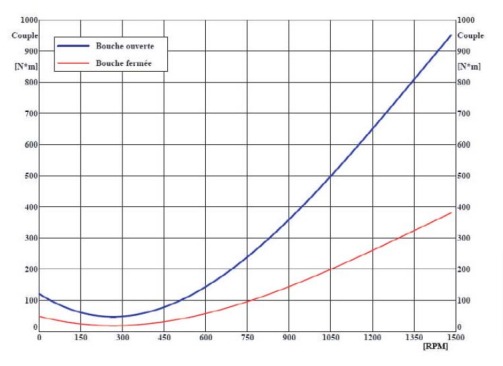

We know that the resistive torque of a fan is a parabola, as it is equal to the square of the speed (Cr= kN²) except for lower speeds for which the passive resistances has to be included. We should then ensure that the motor will be able to deliver the necessary torque at the considered speed.

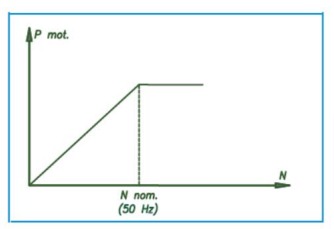

Considering the speed, the electrical motor delivers a power directly proportional to the speed between N=0 and N corresponding to the network power supply at 50 Hz (for ex: from 0 to 1500 RPM, for a 4 poles motor). But as we crossed the 50 Hz, the delivered power remains constant (see chart below) and the torque will evolves reversely to the speed, according the formula C= P/(πN/30), with P= constant.

If the motor is sized initially to give enough power at the nominal speed, it is not necessary to worry about the capacity of the motor to deliver sufficient torque at partial speed. The torque motor (constant) is always higher than the parabola of the resistive torque.

In contrary, above the nominal speed, it is necessary to check it in order to avoid unpleasant surprise.

Let’s take for example the case of a fan which should operate at different speeds and with following power:120 kW @ 1480 RPM and 237 kw @ 1966 RPM.

At the first look, a 250 kW motor seems to be enough to cover both working points. Absolutely not!

Indeed! According the formula P= C x ω = C x (2πN/60), we got Cr @ 1966 RPM = 237000/(2π x1966/60)= 1151 Nm. In another side, the motor torque @ 1966 RPM is weaker than @ 1500 RPM, and decrease linearly with the speed above the 50 Hz according the formula P= C x ω as P = 250 kW and remains constant above the nominal speed of the motor (1480 RPM à 50 Hz):

Cm @ 1480 RPM= 250000/(π x1480/30)= 1613 Nm. Therefor Cm @ 1966 RPM= 1613 x 1480/1966 = 1214 Nm

At the first look, 1214 Nm is higher than 1151 Nm, the sizing seems to be sufficient. We should anyway take into account that the 1214 Nm could be the delivered torque is the network supply delivers exactly 66 Hz to reach the 1966 RPM. Here, the 66 Hz are “manufactured” by a variable speed drive generating harmonics that can create losses and avoid the fan to deliver the total expected torque.

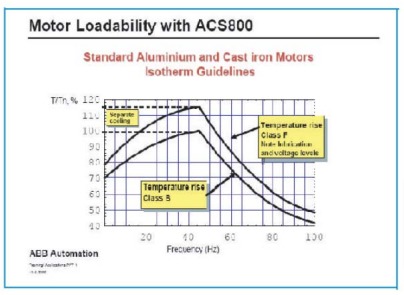

According the curve below, if we want that the motor operates with a B heating, the torque available will be:

Cm =1613 x 0.68 = 1096 Nm, in place of the 1214 Nm theoretically calculated above, and is insufficient to reach the desired working point.

We will then select a motor with higher power range

315 kW.