Centrifugal Fans Sodeca

Axial Fans Sodeca

Standard Roof fans Sodeca

Inline Fans Sodeca

Availability and assistance

Smoke Extraction Fans

Air Vision Warranty

Options and accessories

Vibration en aeraulic measurement

Mounting and maintenance

A large range of centrifugal fans for industrial ventilation processes with pressure up to 1600 mmCE.

Centrifugal Fans

CRL – Low Pressure

Centrifugal fans with airflow from 1.350 to 12.080 m³/h.

Sheet steel casing and sheet steel reaction blade turbine, for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2-4 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CMR – Low & Medium Pressure

Centrifugal fans with airflow from 5.160 to 75.000 m³/h.

Sheet steel casing and sheet steel reaction blade turbine, for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CMP – Medium Pressure

Centrifugal fans with airflow from 135 to 21.000 m³/h.

Sheet steel casing and impeller with forward inclined impeller in galvanized sheet steel, for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, single or three-phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CMA – Medium & High Pressure

CMA – Medium & High Pressure

Centrifugal fans with airflow from 265 to 3.550 m³/h.

Casing and impeller made of cast aluminium (polyamide impeller for models 324, 325 and 426, sheet steel impeller for models 531-2T-3), for maximum temperature of 120°C. IE3 motors class F with ball bearings and IP55 protection, single or three-phase, 2 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CAM – High Pressure

Centrifugal fans with airflow from 2.430 to 11.390 m³/h.

Sheet steel casing and cast aluminium impeller (sheet steel for models 752, 880, 980), for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CAS – CAS-S – High Pressure

Centrifugal fans with airflow from 450 to 42.600 m³/h.

Sheet steel casing and backward inclined impeller made of galvanised sheet steel, for a maximum temperature of 120°C. Design (CAS-S) with hexagonal sound attenuator incorporated in the fan inlet of the fan to adjust the air flow rate at the intake. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CA – Very High Pressure

Centrifugal fans with airflow from 220 to 2.300 m³/h.

Casing and impeller made of cast aluminium, for a maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CMAT – Dusty Air Transportation

Centrifugal fans with airflow from 300 to 3.115 m³/h.

Cast aluminium casing and straight blade impeller, made of cast aluminium for models 324 to 531 and sheet steel for models 540 to 545, for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

CMT – Dusty Air Transportation

Centrifugal fans with airflow from 1.080 to 13.600 m³/h.

Sheet steel casing and straight blade impeller, for maximum temperature of 120°C. IE3 class F motors with ball bearings and IP55 protection, three-phase, 2-4 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

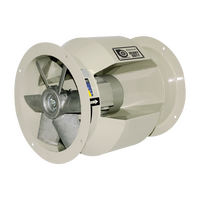

A large range of axial fans for wall mounting applications upto diameter 1000 mm and mounting in ductwork upto 1600 mm.

Axial Fans

Fan HEP – HEPT

Fan HEP – HEPT

Axial fans with airflow from 1,250 to 18,700 m³/h with diameters from 250 to 630 mm.

Wall-mounted version with sheet steel support frame (HEP) and tubular version with sheet steel casing (HEPT), each with glass fibre reinforced polyamide 6 impeller. IE3 class F motors with ball bearings and IP65 protection, single or three-phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

Fan HC

Fan HC

Axial fans with airflow from 2,200 to 54,000 m³/h with diameters from 250 to 1,000 mm.

Wall-mounted version with sheet steel support frame, with glass fibre reinforced polyamide 6 impeller. IE3 class F motor with ball bearings and IP65 protection, single or three-phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

Fan HCH – HCT

Axial fans with airflow from 1,000 to 71,850 m³/h with diameters from 250 to 1,000 mm.

Wall-mounted version with sheet steel support frame (HCH) and tubular version with sheet steel casing (HCT), including impeller version PL made of glass fibre reinforced polyamide 6 or version AL made of cast aluminium. IE3 class F motors with ball bearings and IP55 protection, single or three-phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

Fan CJHCH

Fan CJHCH

Axial fan with airflow from 11,050 to 71,850 m³/h with diameters from 560 to 1,000 mm.

Galvanized steel structure with thermal and acoustic insulation, with glass fiber reinforced polyamide 6 propeller. IE3 class F motors with ball bearings and IP55 protection, three-phase, 4-6 poles. Anti-corrosion finition in galvanized steel sheet.

Fan HBA

Axial fan with airflow from 2.900 to 21.700 m³/h with diameters from 310 to 1.000 mm.

Bifurcated tubular execution in steel sheet for air circulation up to 150°C continuously and up to 200°C sporadically, with cast aluminium impeller. IE3 class F motors with ball bearings and IP55 protection, single or three phase, 2-4-6 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

Fan HGI

Axial fan with airflow from 16,000 to 43,000 m³/h with diameter from 800 to 1,250 mm.

Wall-mounted version with a large diameter, designed for high air flows at low speed, with an automatic opening damper. Supporting frame in sheet steel and galvanized steel structure, with galvanized impeller and anti-contact protection grid. Fan specially designed for applications in farms and greenhouses. IE3 class F motors with ball bearings and IP55 protection, three-phase. Anti-corrosion finition in galvanized steel sheet.

Fan HGT – HGTX

Axial fans with airflows from 45,700 to 207,500 m³/h with diameters from 1,250 to 1,600 mm.

Large diameter sheet steel tubular design with direct motor (HGT) or external motor (HGTX), with 6 or 9 blade cast aluminium impeller for various angles of inclination. Standard version with short frame (HGT) or long frame equipped with an inspection hatch (HGTX). IE3 class F motors with ball bearings and IP55 protection, three-phase, 6-9 poles. Polyester resin finish polymerized at 190°C with anti-corrosive properties, including pre-greasing with nanotechnological treatment without phosphates.

Fan HPX

Axial fan with airflow from 2,500 to 68,000 m³/h with diameters from 350 to 1,000 mm.

Transmission driven tubular design, with sheet steel rotating cover casing, with cast aluminium impeller and sealed transmission unit with double retaining ring system. IE3 class F motors with ball bearings and IP55 protection, single or three-phase, 2-4 poles. Anti-corrosive finish of polyester resin polymerized at 190ºC, previously degreased with phosphate-free nanotechnological treatment.

Roof Fans

Axial fans

HT

Airflow upto 28.200 m³/h.

HT/EC

Airflow upto 28.200 m³/h.

HTMH

Airflow upto 73.870 m³/h.

HTMV

Airflow upto 92.950 m³/h.

Centrifugal fans

CHT

Airflow upto 24.700 m³/h.

CHT/EC

Airflow upto 6.900 m³/h.

CVT

Airflow upto 24.700 m³/h.

CVT/EC

Airflow upto 6.900 m³/h.

Inline Fans Sodeca

Centrifugal inline fans SVE/SVE Plus

Centrifugal inline fans CL

You can reach us 24/7, 365 days per year, by phone 32.10.47.00.80

Very quick response and solutions for troubleshooting ensuring your production safety.

Smoke Extraction Fans

Axial smoke extraction fans

Roof smoke extraction fans

Axial Booster smoke fans

Overpressure systems for staircases

Unique experience of the industrial process. Customer service and assistance for designing the fan. The best buy : reliability, long-life, investment cost and running cost. Personalized service during all the fan life operation.

To spare you all the worries of integration and logistics, we are expanding our supply including silencers, dampers, filters and all the related frames and supports and completely mounted on site.

Aeraulic measurement campaings on existing installations allows the customer to optimise the duty of the fans, or ease the redifinition of the fans according the new working conditions.

Vibration measurements are a main factor in the predictif process of maintenance in order to avoid unplanned shut downs of the production process.

On demand, we ensure the mounting supervision or mounting itself of the fans delivered.

Our planned maintenance work fit with your production shutdowns for preventive and predictive maintenance. Our teams works with modern technology devices for balancing and alignment of the fans.